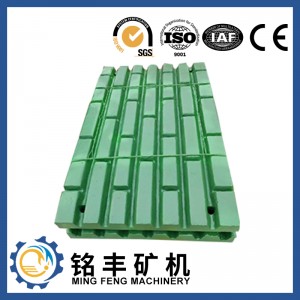

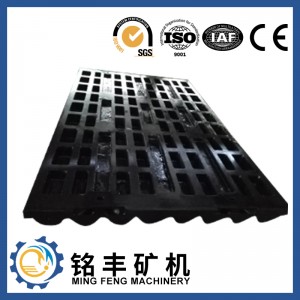

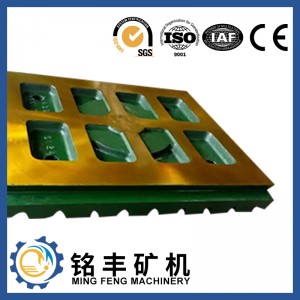

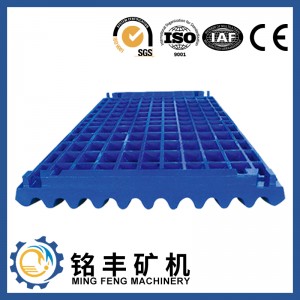

Simbi yejecha yekukanda zvikamu mune quarry mining stone plant

1. Material: High manganese simbi, alloy simbi.

2. Molding processing: Kukanda jecha kana kurasikirwa kwefuro

3. Zvivako zvekunyunguduka: Medium frequency electric induction furnace / magetsi arc furnace.

4. Casting Inspection: Direct-reading spectrum instrument, metallographic analysis, ultrasonic inspection, magnetic particle inspection, mechanical properties inspection.

5. Heat kurapwa zvivako: Special kudziyisa emagetsi hovhorosi, inokosha mvura madziva etc inokosha quenching equipments.

6. Kurapa kwepamusoro: Shot blast kuchenesa.

7. Zvikamu zvemaindasitiri: Indasitiri yeinjiniya yekuvaka, kugadzira zvicherwa, indasitiri yekudzokorodza, zvimiro zvezvikamu zvekuchekesa, indasitiri yemuchina wemuchina, ngarava yekudhonza, indasitiri yengarava yeinjiniya nezvimwe.

8. Mushandisi-ushamwari, nyore disassembly uye ungano

| Yakakwira Manganese Kukandira Material Chemical Kuumbwa | |||||||

| Code Elem. | C | Mn | Si | Cr | Mo | P | S |

| ZGMn13-1 | 1.0-1.45 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-2 | 0.90-1.35 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-3 | 0.9-1.35 | 11.0-14.0 | 0.30-0.8 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-4 | 0.9-1.30 | 11.0-14.0 | 0.30-0.8 | 1.50-2.0 | - | ≤0.09 | ≤0.04 |

| ZGMn13-5 | 0.75-1.30 | 11.0-14.0 | 0.30-1.0 | - | 0.90-1.2 | ≤0.09 | ≤0.04 |

Zvakanakira:

1. Top inopfuurira kupwanya kuita.

2. Mutengo wakaderera patani yakapwanyika nekuwedzera hupenyu hwekupfeka.

3. Kuwedzera nguva yekugadzira nekuda kwekuderedzwa nguva.

4. Kuwedzera kuchengetedzwa nekuda kwekushomeka kwechikamu chekuchinja-kunze.

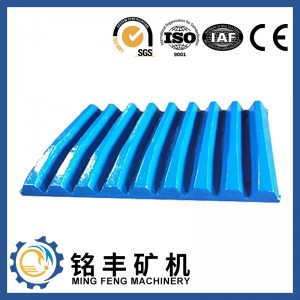

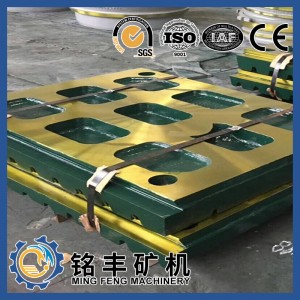

Zvikamu zveCrusher:

Tine precision machined replacement crusher spare parts zvinosanganisira jaw plate, jaw plate wedge, pitman, main frame, pulley, yekumusoro side plate, yezasi side plate, toggle plate nezvimwe, tinokwanisa kutsigira muchina wako wese wemechanical spare parts.

Sei tichisarudza isu?

1.30 makore ekugadzira ruzivo, 6 makore ekunze kwekutengeserana ruzivo

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Hunhu Kutanga, Kuchengetedzwa Kwakavimbiswa